The Role of Robotics in Industry 4.0: Automation and Efficiency

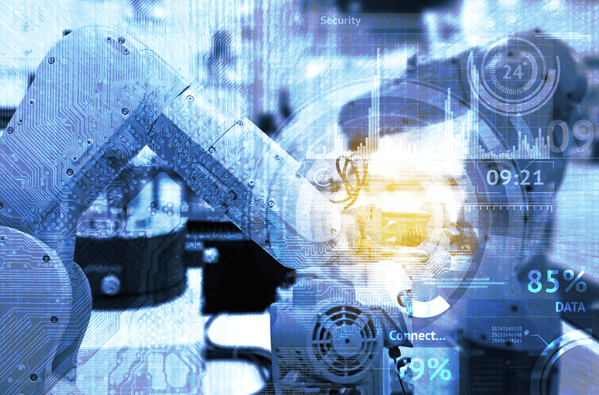

The integration of robotics within the framework of Industry 4.0 marks a significant shift in how industries approach automation and efficiency. By leveraging advanced robotic systems, organizations can streamline manufacturing processes, reduce human error, and enhance overall productivity. This transformation not only fosters a more agile operational environment but also raises critical questions about the future of workforce dynamics and the implications for sustainable growth. As we explore the multifaceted impact of robotics, the potential for innovation and adaptation in an ever-evolving industrial landscape becomes increasingly apparent.

Impact of Robotics on Manufacturing

The integration of robotics into manufacturing processes has fundamentally transformed production efficiency and operational capabilities.

Robotic collaboration in smart factories enhances adaptability and precision, allowing for the seamless interaction of machines and human operators.

This synergy optimizes workflow, reduces downtime, and increases output quality, ultimately empowering manufacturers to respond swiftly to market demands while maintaining a competitive edge in an increasingly dynamic landscape.

See also: How AI Face Swap Technology Works Behind the Scenes

Enhancing Automation Processes

Integrating advanced robotics into automation processes significantly elevates operational efficiency across various industries.

By leveraging robotic collaboration, businesses can achieve synergistic interactions between humans and machines, enhancing productivity.

Smart automation systems streamline workflows, reduce manual errors, and optimize resource allocation.

This convergence of technologies fosters innovation, allowing organizations to adapt swiftly to market demands while maintaining the flexibility that a competitive landscape requires.

Improving Efficiency in Operations

Optimizing operational efficiency is a critical objective for organizations aiming to thrive in the competitive landscape of Industry 4.0.

Through robotic collaboration, companies can enhance productivity while maintaining operational agility. This synergy allows for adaptable workflows and real-time decision-making, reducing downtime and increasing throughput.

Ultimately, the integration of robotics fosters a dynamic environment where efficiency is continuously improved, driving sustainable growth.

Future Trends in Robotics

As organizations continue to leverage robotics to enhance operational efficiency, the landscape of robotic technology is poised for significant evolution.

Future trends will likely focus on:

- Increased adoption of collaborative robots

- Advanced AI integration for smarter decision-making

- Enhanced human-robot interaction capabilities

- Development of more versatile robotic innovations

- Greater emphasis on sustainability and energy efficiency

These advancements promise to redefine industrial processes and workforce dynamics.

Conclusion

The integration of robotics within Industry 4.0 represents a transformative leap towards unprecedented levels of automation and efficiency. As machines and human operators increasingly collaborate, operational workflows are streamlined, significantly reducing manual errors. This convergence not only amplifies productivity but also equips organizations to swiftly adapt to shifting market demands. Future advancements in robotics promise to further enhance these capabilities, solidifying the role of automation as a cornerstone of sustainable industrial growth and innovation in an ever-evolving landscape.